Description

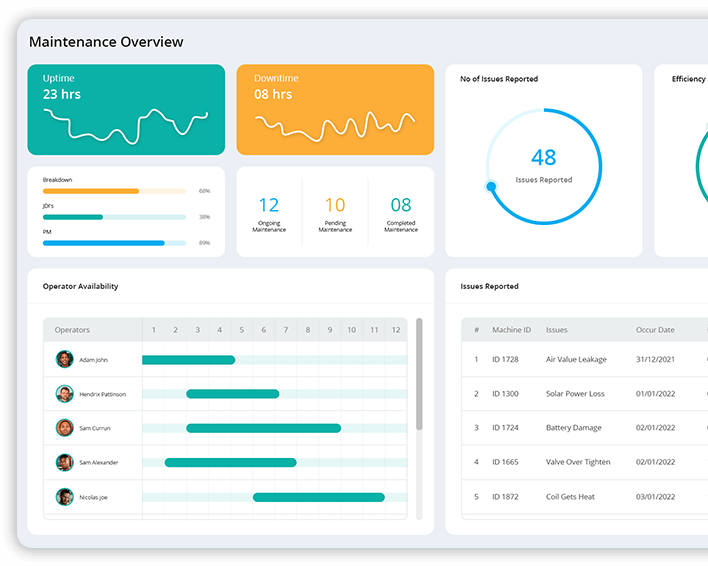

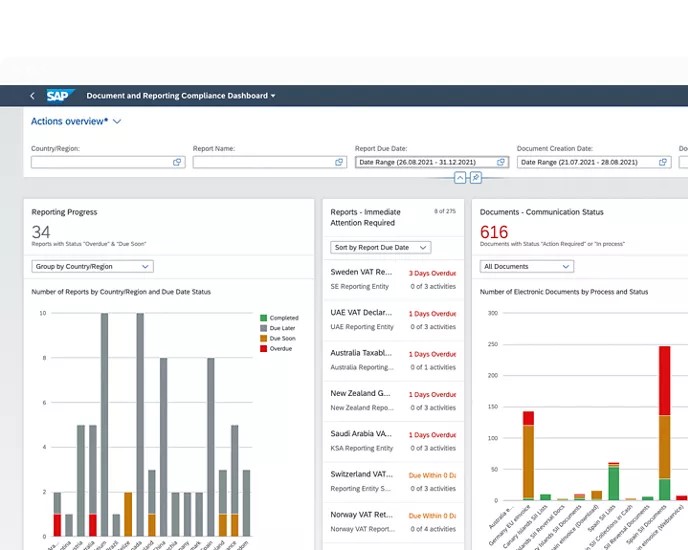

The Predictive Maintenance Management Software is an AI-driven platform that transforms traditional maintenance into a proactive, data-centric strategy. By analyzing real-time equipment performance data, vibration signals, temperature variations, and electrical anomalies, the system forecasts potential failures before they disrupt operations. Using machine learning algorithms, it establishes performance baselines for each asset, detecting deviations that indicate wear, imbalance, or component degradation. The software integrates with IoT sensors, SCADA systems, and CMMS databases to continuously monitor asset health across facilities. Predictive models automatically prioritize maintenance tasks based on risk severity, cost impact, and downtime probability. Engineers receive instant alerts and actionable insights via web and mobile dashboards, allowing for targeted intervention instead of reactive repairs. The system also calculates remaining useful life (RUL) for critical equipment, helping managers optimize maintenance budgets and spare parts inventory. Comprehensive reporting and visualization tools provide trend analysis, root-cause diagnostics, and performance benchmarking across plants. For enterprises managing high-value electrical assets — such as transformers, switchgear, and motors — this software significantly reduces unplanned downtime, enhances reliability, and extends equipment lifespan. It embodies the evolution of maintenance into a predictive, intelligent, and efficiency-driven discipline.

Cosmos –

Predictive Maintenance Management Software” transformed our reactive maintenance into proactive strategy. Identifying subtle anomalies weeks before failure saved us critical downtime. The team’s seamless integration and responsive support made adoption effortless. Our ROI is already exceeding expectations thanks to optimized asset lifespan.

Adeola –

Predictive Maintenance Management Software” has been a game-changer for our plant. We’ve seen a tangible reduction in unexpected outages, thanks to the AI’s accurate predictions. The streamlined maintenance scheduling and responsive support team have significantly improved our operational efficiency.

Uchenna –

Predictive Maintenance Management Software” eliminated unplanned outages in our aging facility. We saw a 20% reduction in downtime within the first quarter. The AI’s accuracy is impressive, and the support team proactively helped integrate it seamlessly. Truly a game-changer for our electrical maintenance strategy.

Ai –

Predictive Maintenance Management Software” moved our factory from reactive fire-fighting to proactive planning. Unexpected outages dropped significantly within the first quarter. The intuitive interface and responsive support team made implementation seamless. We’re now optimizing resource allocation based on data, not guesswork. A game changer for uptime.